Vapor Recovery Units: history and technologies

History

In 1994, the European Union enacted Directive 94/63/EC affecting terminals for the storage and distribution of petroleum products, with the objective of controlling and limiting the emission of volatile organic compounds (VOCs) into the atmosphere through a Vapor Recovery Unit. In this directive, the emission level of hydrocarbon components is limited to 35 grams of HC per cubic meter of gas expelled into the atmosphere. EU member states have to comply with this emission level as a minimum, but have the right to require lower levels depending on local circumstances. Phase I of this directive (recovery of all vapors from service station ground tanks back to the truck and recovery during truck loading at the storage and distribution terminal) has been adopted and implemented by each member of the European Union. Phase II of the directive (recovery of vapors from cars at the service station) has only been partially implemented (especially in the northern European states).

Based on the adage "the lower the emission to the atmosphere... the better", some countries implemented emission levels in the milligram range, despite a sharp increase in energy consumption to get there. However, studies by independent laboratories indicate that there is an optimal relationship between emission level and energy consumption for the reduction of hydrocarbon emissions. The fact is that electric power generation in most cases is carried out by burning petroleum fuels in power plants and this process also creates emissions to the atmosphere. The optimum level of emissions for a Vapor Recovery Unit based on activated carbon with dry vacuum regeneration techniques is about 2 grams of hydrocarbons per cubic meter of air emitted to the atmosphere. For systems with higher electrical consumption per cubic meter of gas treated (liquid ring systems and membrane systems) the optimum moves up to about 5 grams per cubic meter.

The installation of vapor recovery units at oil product terminals in the European Union has been carried out in stages, starting with large terminals, while the last batch of systems at smaller terminals was to be operational by 2004.

Technologies

There are basically four different technologies on the market today:

- Adsorption of hydrocarbons on activated carbon followed by vacuum regeneration and reabsorption in one of the products stored at the terminal.

- Cooling of the vapor mixture causing condensation of part of the hydrocarbon components,

- Washing techniques with a cold liquid,

- Compression of the vapor mixture followed by membrane separation techniques.

Currently, most of the world's production, storage and distribution companies prefer the adsorption process with activated carbon using dry screw vacuum technology. Deep cooling and cold washing techniques have been abandoned on a large scale since the 1980s due to high energy consumption and maintenance costs. Membrane systems, with limited possibilities to obtain the required low emission level and high energy consumption, are mainly used for special products with almost continuous flow rates.

There are several versions of vapor recovery units based on activated carbon that use vacuum for carbon regeneration.

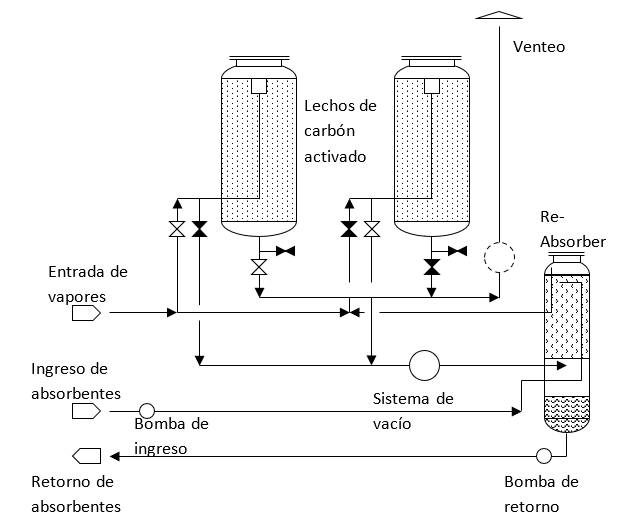

But they are all based on the same principle:

- Adsorption of the hydrocarbon part of the vapor on the activated carbon filter in line with the loading operation (the other is in regeneration/next step). The clean air will be passed to the atmosphere.

- Once the activated carbon filter is filled with hydrocarbons, it goes into regeneration mode which proceeds with a vacuum pump.

- The recovered gas is highly concentrated and is finally washed into a reabsorption column where a counter flow of liquid will draw the vapor down to the bottom liquid which is pumped to the terminal storage facility.

The oldest version of a vapor recovery unit is that of Rheem Brothers of the USA, which introduced the technology in the early 1970s using liquid ring vacuum pumps to regenerate activated carbon. This technology is still used by many Vapor Recovery Unit suppliers, as the cost price of the liquid ring pump is low. However, the maintenance cost and energy consumption of this technology are relatively high. The circulation of the sealing liquid required to maintain the liquid ring inside the pump causes high levels of corrosion and the formation of rust particles that create abrasion on the piping and inside the pump. The gradual loss of pumping capacity over a prolonged period results in ineffective regeneration of the activated carbon with loss of activated carbon life time. In addition, the solubility of some of the components present in the oil product vapors can lead to a loss of capacity.

Another alternative is the use of mechanical piston pump, but essentially the need for maintenance, life time and energy consumption are major disadvantages of that solution.

In 1999, Mr. Ties Mulder of SYMEX was the first to use a new vacuum pump technology, based on the dry screw principle, in a vapor recovery unit. The dry screw pump eliminates the need for a sealing liquid and the associated corrosion and abrasion. Unlike the liquid ring pump, the dry screw pump can be speed controlled. This opens up the possibility of tailoring the capacity requirement seamlessly to varying flow rates and concentrations in the vapor mixture presented to the Vapor Recovery Unit. Today, SYMEX vapor recovery unit technology is the most widely used vapor recovery unit technology on the market.

Our dry vacuum vapor recovery unit technology is characterized by:

- Longer service life of vacuum pumps:

- No internal parts touching, no internal wear

- Overhaul of pumps only after more than 40,000 operating hours

- Longer service life of activated carbon

- Activated carbon does not move: no damage

- Pressure-controlled desorption process

- Optimized pore size distribution

- Low pressure loss

- Minimized energy consumption

- Pumping process requires 50% less energy

- Pumps are frequency controlled

- Regeneration energy proportional to the mass of HC adsorbed

- Lower maintenance cost

- No corrosion or abrasion

- Easier process

- Selection of high quality equipment

- Wide range of treated products

- Alcohol (methanol, ethanol)

- ETBE

- MTBE

- Benzene, Toluene, Xylenes (BTX)

- Crude oil

- Gasoline, Naphtha, etc...

Our Vapor Recovery Units certified ATEXare installed all over the world in oil and petrochemical production, storage and distribution plants, with loading facilities on ships, trucks and rail cars, in varying climatic conditions (-50°C in Canada or Russia, + 55°C in the Middle East) and for a wide range of applications. We are at your disposal to investigate and study the feasibility of implementing a vapor recovery unit in your plants.

If you have any questions, please contact us via contact form, or our datasheet. We will be glad to help you.