Internal floating roofs

Internal Floating Roofs were developed more than 90 years ago to reduce evaporative losses and limit explosive environments.

There are two families of Internal Floating Roofs : pontoon-type, or full contact.

We have worked hard to offer a revolutionary solution to the problems encountered by end-users.

Some features:

- No closed compartments that trap vapors: the safest one

- Live load 12.5psf, modulus of elasticity 35ksi: the strongest. As strong as Steel Internal Floating Roofs.

- No other IFR lets so few VOC emissions through

- Excess buoyancy 460%

- No drain

- A simple visual inspection allows for a complete check-up

- Possibility to weld the aluminum due to the thicknesses used

- They work perfectly with our geodesic dome roofs

If you have any questions, please contact us via Whatsapp, our contact form, or our datasheet. We will be glad to help you.

Our Floating Internal Roof solves the following issues:

Safety

It is a fact: whether with floats or full contact type, the other internal floating roofs let vapors enter in closed compartments (under the deck in case of pontoons, in the pontoons themselves, in the honeycombs, etc.). These enclosed vapors are very dangerous:

- You do not know at a glance if they are full of vapors

- They can escape (and they will!)

- They are corrosion-free points

Drain

Drains are sources of many problems for internal floating roofs:

- Emission of vapors

- Water entry into the product (contamination, bacteria, corrosion in particular floor/shell junction)

- Air/liquid interface at drain level (corrosion-free)

- Rarely correctly located

- Weaken the structural strength of the IFR

Internal Floating Roof GRP (Glass Reinforced Plastic) and GRE (Glass Fiber Reinforced Epoxy Vinyl Ester)

Full contact internal floating roof (IFR) design composed of glass fiber.

Seamless installation process

Choice of material of construction based on chemical environment.

Exceptional chemical resistance to almost all petrochemicals, including electrically conductive liquids such as ethanol and methanol.

Inspection

It is impossible to perform a visual inspection to detect the problems of the other internal floating roofs. How can you tell if a pontoon is punctured and has product inside? The same with a honeycomb or any closed compartment! It is impossible without emptying and degassing the tank!

Our full contact internal floating roof can be fully checked with a simple visual inspection!

Robustness

Many internal floating roofs are very fragile, offering very low mechanical resistance. They cannot be hung from the ceiling, they can only come with support legs. They do not resist earthquakes very well. Walking on those IFR becomes dangerous for both the user and the deck

The full contact floating internal floating roof has a live load of 12,5psf and a elastic modulus of 35ksi.

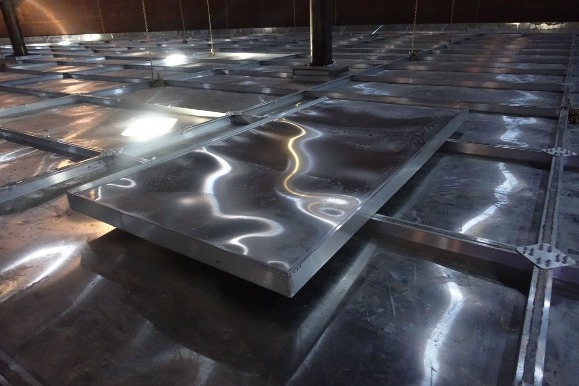

Pontoon type Internal Floating Roofs

Typically pontoon-type Internal Floating roofs can be constructed of aluminum, stainless steel or a combination of both, called hybrids (all parts in contact (wetted) with the product in stainless steel). All our IFR´s fully comply with API 650.

Internal Floating Roofs are also known as Internal Floating Screens.