Marine Loading Arms: Cost of Ownership

Introduction

Zero cost of ownership is the ultimate objective for any installation, but especially for marine loading arms. But is that a realistic objective? The obvious response is "no." However, a well-considered plan would go a long way towards achieving this objective when it comes to loading facilities. The foundation of businesses that generate, trade, or offer storage space for these fluids is fluid transfer.

Ultimately, it is the flow of fluids that keeps the meters counting and generates the cash flow.

The loading/unloading facility, which is the most important step in moving fluids from a storage tank to an oil tanker, is the last section of the fluid transfer line that will be covered in this article.

The liquid transfer line's loading facility is a flexible component since it must follow both horizontal and vertical movements. This flexibility necessitates the use of loading hoses or loading arms, which puts it at danger from emergencies, malfunctions, and general wear and tear.

Fig 1: marine loading arms in operation

Loading and unloading process at the jetty

Oil tanker loading and unloading is a dangerous process that involves several risks. It is simple for mishaps to happen throughout any of the operational phases because of the transport vessel's intrinsic dynamics while connection and loading.

Due to their flexibility, hoses and marine loading arms are two options for moving liquids between a storage tank and an oil tanker. Hose connections between ships and shores provide more flexibility, but in comparison to loading arms, they are more prone to wear and breakage, have a shorter service life, and take more work to operate.

Hoses typically have periodic testing and inspections, once or twice a year, and as a result have an annual cost of ownership.

In terms of safety, hoses hardly ever have quick-acting emergency release mechanisms with "zero" spillage, and none have automatic emergency release options.

Fig 2: A typical jetty layout for loading arms

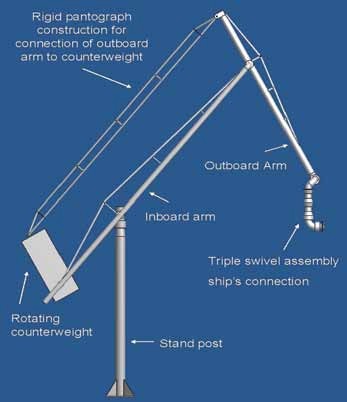

Fig 3: Modern design with pantograph

The connections made by the marine loading arms achieve a fully rigid connection, but with the possibility to follow all movements of the ship through the use of swivel joints between the steel pipes, thus solving the disadvantages of the loading hoses. They can also be executed with automatic "no-spill" emergency release uncouplers and fitted with motorized quick couplers to increase personal safety and protect the environment. desacopladores automáticos de liberación de emergencia “sin derrame” y equiparse con acoplamientos rápidos motorizados para aumentar la seguridad personal y proteger el medio ambiente.

The structural design of marine loading arms is a very important factor when considering the maintenance required. The human factor contributing to the cost of ownership is not always visible, but is closely related to the operating comfort and maintainability of the loading arms. Any difficulties in day-to-day operation and maintenance procedures will have a decisive impact on operators.

Installation, use, and maintenance of loading arms must be planned with operators and maintenance people in mind, and they must be simple enough for a single person to operate. For instance, it is best to avoid utilizing flexible cables with pendants to regulate the loading arm on a regular basis because they might lead to accidents and are vulnerable to damage, which could result in unexpected movements of the arms. los cables flexibles con colgantes para el control regular del brazo de carga deben evitarse, ya que pueden causar accidentes y son propensos a dañarse, provocando así movimientos inesperados de los brazos.

Fig 4: pantographe vs cable

Design of the marine loading arms

The design of the loading arms is something that is worth paying close attention to because it is important for maintenance. With the right structural arrangement and a straightforward loading arm design, the cost of ownership can be nearly negligible. simplicidad del diseño de los brazos de carga combinada con una configuración estructural óptima permitirá un coste de propiedad cercano a cero.

Counterweight balancing: rigid link versus cable link

The moveable parts, called inboard arm and outboard arm, are

counterweight balanced (see fig 3). The inboard and outboard arms of marine loading arms may each have a distinct spinning counterweight, or the inner and outer arms may each have a combined rotating counterweight. A rigid pantograph system or a rope and pulley arrangement can be used to connect the loading arm's moveable tubes to the counterweight (see Figure 4).

A cable and pulley system needs regular inspection, greasing and retensioning, whereas a system with a rigid connection, the balancing is adjusted once at the factory and never again. un sistema con una conexión rígida, el balanceado se ajusta una vez en la fábrica y nunca más.

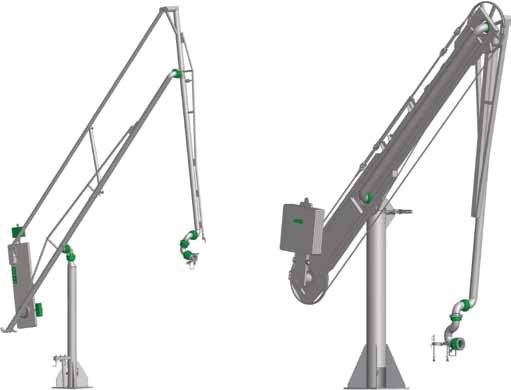

Fig 5: symetric marine loading arm

Self-supporting structure versus separate support frame

The pipe carrying the liquid may be supported by a structure that carries the entire weight of the liquid line. This configuration is complex and should be avoided for all applications other than cryogenic or extremely corrosive fluids. Improvements in swivel joint design have eliminated the need for a separate support structure, even for extremely large dimensions. This means that self-supporting load arms can be standard, which is a significant improvement towards the goal of simplicity. autoportantes pueden ser un estándar, lo que supone una mejora significativa hacia el objetivo de la simplicidad.

Swivel joints

The performance of marine loading arms depends on the swivel joints. Modern high-performance swivel joints allow years of leak-free operation without the need for regular greasing and maintenance. A multi-year warranty, including all swivel joints, is essential to achieve zero cost of ownership. funcionamiento sin fugas durante años, sin necesidad de engrasarlas periódicamente ni mantenimiento. Una garantía de varios años, que incluye todas las articulaciones giratorias, es esencial para conseguir un coste cero de propiedad.

Marine loading arms configuration

Marine loading arms with symmetrical design characterised by the recommended self-supporting structure and rigid coupling have excellent reliability due to the equal division of forces throughout the structure.

(see figure 5). With basic maintenance limited to a few greasing points, the uptime is virtually 100% and the cost of ownership is practically zero. It is also advisable to consult the publications from OCIMF.

Conclusion

Modern, symmetrical marine loading arms with rigid linkage and self-supporting structure and executed with high performance swivel joints provide close to zero cost of ownership for fluid transfer operations. Additional attention to simple and intuitive operation will further minimize operating costs.

If you have any questions, please contact us via Whatsapp, our contact form, or our datasheet. We will be glad to help you.